THERMOSET IN-MOLD FINISHING FILM

In-mold coating (IMC) generally involves the production of a coated molded article by means of a process in which a coating film is inserted into a mold and then a resin is injected into the mold to perform injection molding, thereby transferring the coating resin of a transfer layer provided in the coating film onto a surface of the molded article.

In-mold decorating (IMD) generally involves the production of decorated molded article by means of a process in which a decorative film is inserted into a mold and then a resin is injected into the mold to perform injection molding, thereby decoratively transferring the pattern of a transfer layer provided in the decorative film onto a surface of the molded article.

While injection molding is the most commonly used IMC and IMD fabrication process, alternative processes [such as compression molding, spin casting, rotational molding, thermoforming, roll lamination, use of a platen/laminate press, blow molding, resin transfer molding (RTM), or reaction injection molding (RIM)] are also sometimes used. Injection molding is suitable for processing thermoplastic resins during IMC and IMD operations, while RIM enables the use of injection molding in IMC and IMD processes that require the molding of thermoset polymers.

Most IMD methods are transfer methods where an image is printed on a carrier film or carrier sheet and then “transferred” to a molded article during the molding process. Some IMD methods use a carrier film or carrier sheet with a durable coating resin that is printed and both the coating and decoration are transferred to the molded article during molding to produce a more durable decoration.

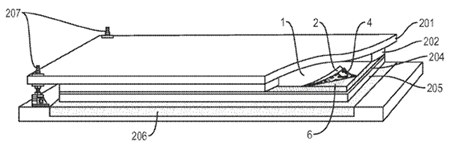

Existing IMC and IMD technologies using the RIM process to incorporate a thermoset layer for enhanced durability have many limitations. Hence patented technology, not suffering from the limitations of the prior art technologies, was developed for the manufacturing of durable thermoset in-mold finishing films (TIMFFs) combining in-mold decorating and in-mold coating capabilities, for thermosetting resin formulations used in the manufacturing of TIMFFs, and for molded articles having TIMFFs adhering to their surfaces and both showing a decoration and providing protection. Several different approaches for manufacturing TIMFFs, a broad range of thermosetting resin formulations that can be used for manufacturing TIMFFs, and the vast range of potential application opportunities that exist for TIMFFs are taught in the patent. The images shown below were all reproduced from this patent.

TIMFF prototypes were prepared successfully by using polyurethane chemistry implemented via RIM. The technology is currently being scaled up for commercialization. Targeted applications include use in graphic panels for durable signage and structural graphics, molded flooring products, prefabricated housing wall or roof components, structures or body panels in transportation vehicles, and any other applications for which a TIMFF can be customized for the IMC and IMD of a fabricated article.

ColorSet Composites are the first products commercialized based on this versatile technology. Work is in progress to develop and scale up additional commercial products for many applications.