COMPLETELY MICROBIAL POLYESTERS: POLYHYDROXYALKANOATES

Microbial polyesters were mentioned briefly in a post titled BIOBASED FEEDSTOCKS (created 17 November 2018). The present post will cover one class of these materials, whose importance and range of applications are growing rapidly as the polymer industry continues to strive for increased sustainability, in greater detail.

Microbial polyesters can be subdivided into two major classes.

- Some microbial polyesters are produced by polymerizing monomers prepared by a fermentation process. Hence the production of these polyesters does not happen entirely via microbial processes. Microorganisms produce the monomers, but synthetic polymer chemistry must then be used to produce the polymers from these monomers. Poly(lactic acid) is the most important example of this class of semi-synthetic polyesters. This class of polyesters falls outside the scope of the present post.

- Some other microbial polyesters are produced entirely by microorganisms. These completely microbial polyesters are direct products of the metabolic processes of the microorganisms. The present post will focus on this class of polyesters.

Polyhydroxyalkanoates (PHAs) constitute the most important family of completely microbial polyesters. PHAs are produced commercially by microorganisms (such as the bacteria Cupriavidus necator, Azohydromonas lata, Ralstonia Eutropha, species from the Alcaligenes genus, and recombinant Escherichia coli) that accumulate them as energy storage materials when cultured by using suitable nutrients in suitable environmental conditions. Suitable nutrients include beet and cane molasses, corn starch, alcohols, and vegetable oils. Fermentation strategies are also under development to improve and scale up the production of PHAs by some other bacteria.

PHAs are biobased, renewable, environmentally friendly (since they reduce CO2 emissions), biocompatible, and biodegradable. They possess properties and performance characteristics which make them suitable for a broad range of applications, including not only various medical and biomedical applications but also some applications for which polymers derived from fossil fuel based feedstocks were the only choices until recently.

The following are the most widely commercially available PHAs:

- Poly(3-hydroxybutyrate) (P3HB).

- Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (P3HB3HV).

- Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (P3HB3HH).

The molecular structures of P3HB, P3HB3HV, and P3HB3HH, and a transmission electron micrograph of a thin section of Azotobacter vinelandii bacteria containing P3HB granules (white inclusions), are shown below. These images were reproduced from an open access review article by C. Peña et al., Biotechnological Strategies to Improve Production of Microbial Poly-(3-hydroxybutyrate): A Review of Recent Research Work, Microbial Biotechnology, 7(4): 278–293 (July 2014).

The P3HB homopolymer and the copolymers of 3-hydroxybutyrate with 3-hydroxyvalerate or 3-hydroxyhexanoate and/or some other (less commonly used) hydroxyalkanoate repeat units that will be identified below, represent a vast design space of semicrystalline aliphatic polyesters. Within this design space, the crystalline fraction (xc), melting temperature (Tm), glass transition temperature (Tg), and other properties that affect both the processing attributes and the performance of fabricated articles during use, can be varied by varying the type and mole fraction of comonomer and the extent of polymerization as characterized by the number-average and weight-average molecular weight (Mn and Mw).

The P3HB homopolymer provides the highest xc, Tm, Tg, stiffness (Young’s modulus E), and tensile strength (σt), but manifests the lowest impact resistance (and hence the most brittleness and the lowest toughness). In the P3HB3HV and P3HB3HH copolymers, the 3-hydroxyvalerate or 3-hydroxyhexanoate repeat units promote flexibility, so that xc, Tm, Tg, E, and σt all decrease, while the impact strength increases (and hence the brittleness decreases and the toughness increases), with increasing comonomer mole fraction. Different balances of all these attributes are optimal for different applications.

The PHA design space thus obviously resembles the design space represented by the polyethylene homopolymer and the copolymers of ethylene with propylene, 1-butene, and other olefin (alkene) monomers. The main difference from a molecular structure viewpoint is that the PHAs have stronger polar interactions than the polyolefins since the PHAs contain high concentrations of ester linkages while the polyolefins are hydrocarbon polymers. The main difference from a sustainability viewpoint is that the PHAs are biobased while the polyolefins are based on monomers derived from fossil fuels.

P3HB, P3HB3HV, P3HB3HH, and/or other PHAs identified below, are commercially available from several manufacturers. The products of six major manufacturers are discussed below. Helping our clients select the best choices for their applications from among the vast number of such products falls under the scope of our material selection services.

Nodax® is produced by Danimer Scientific (USA). It is a product line that consists of (co)polymers of 3-hydroxybutyric acid with up to 25% of 3-hydroxyvaleric acid, 3-hydroxyhexanoic acid, 3-hydroxyoctanoic acid, and/or 3-hydroxydecanoic acid.

- Inexpensive oils, derived from the seeds of plants such as canola, soy, and palm, are fed to bacteria. After the bacteria produce the PHA product, the biomass is removed by a proprietary extraction process to isolate the final purified PHA product. Customized PHAs, tailored to meet the needs of different applications by providing different physical properties, can also be obtained via a subsequent proprietary reactive extrusion process.

- The products are versatile, adaptable, heat-resistant, UV-resistant, FDA-approved for food contact applications, certified as 100% biodegradable, compostable, capable of providing properties comparable to many petrochemical plastics, custom-formulated to create many types of plastic resins for different purposes, durable enough for high-speed processing, able to withstand high temperatures while in storage, able to preserve food and other stored goods better than many competitors, and capable of bonding successfully with materials such as paper.

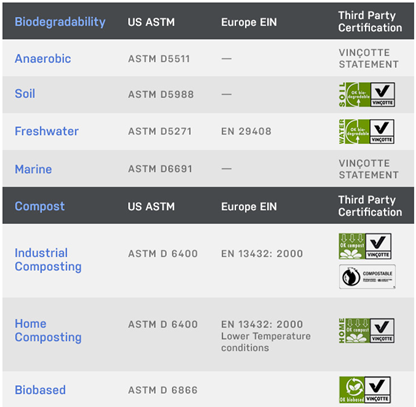

- The biodegradability and compostability certifications are summarized below.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

- The targeted applications include medical implements, cups, beverage bottles, straws, food packaging and storage bags, lids, shopping bags, shipping materials, utensils, diaper linings, plates, wipes, toys, trash bags, agricultural mulch films, flexible films, seals, labels, glues, and many other consumer and industrial goods.

Enmat® is produced by TianAn (China).

- TianAn claims to be the world’s largest P3HB3HV producer.

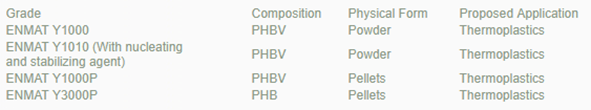

- Enmat® is a family comprising a P3HB product and three P3HB3HV products.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

- ENMAT™ Y1000P has the following typical material properties:

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

- Enmat® is claimed to have several advantages over other commercially available PHAs:

- Use of a non-genetically modified organism (natural strain Ralstonia Eutropha).

- Use of non-genetically modified feedstock (dextrose derived from corn or cassava grown in China).

- Patented water-based extraction technology not involving any solvents or enzymes.

- Smaller carbon footprint as a result of lower energy consumption due to the use of natural strain allowing for fermentation at low temperature.

- The products are certified as compostable, EU food contact approved, and EU Reach compliant.

Biomer thermoplastic P3HB homopolyester pellets that can be processed on standard injection molding machines are produced by Biomer (Germany). The melt behaves like a liquid crystalline polymer, allowing the molding of thin-walled or complex structures even on small injection molding machines. The fabricated articles are waterproof, are heat-resistant, have appealing surfaces, and are fully biodegradable.

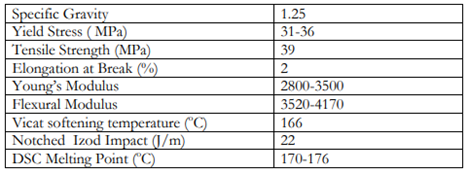

Biocycle® is produced by PHB Industrial S.A. (Brazil).

- This product line consists of P3HB homopolyesters and P3HB3HV copolyesters produced by bacteria from the Alcaligenes genus using sugar cane as the starting material.

- The name “Biocycle” originates from the product lifecycle shown below.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

- A manufacturing process flow chart is shown below.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

- Technical datasheets are provided for four product grades. The products are certified as being biodegradable and compostable. Injection molding, extrusion, thermoforming, and fiber processing can be used as fabrication methods. The main applications are in the production of disposable plastic articles. Medical products for human or veterinary use can also be fabricated. A few examples of fabricated articles are shown below.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

PHBH™ (P3HB3HH in the notation used in this post) copolymers are being produced by Kaneka (Japan) within the scope of its new business development activities. The prospects for the establishment of PHA manufacturing technology utilizing biomasses not used for food as the primary ingredients are being explored. Resin mixes and molding processes are being refined to further improve the strength and tear resistance of packaging films, and especially agricultural mulch films and composting bags. Market opportunities in highly durable molded products, such as bottles, other containers, auto interiors, and electrical equipment are being pursued. The product lifecycle and property data are shown below.

Tepha, Inc. was a leading developer and manufacturer of a proprietary resorbable polymer technology based on PHAs. It was acquired by Becton Dickinson in July 2021. The detailed information below on Tepha's technology was extracted for the original version of this blog post from its website which appears to have been removed after the acquisition. Becton Dickinson has, since then, commercialized the Bioresorbable PhasixTM Mesh based on Tepha's technology.

- Unlike the five manufacturers discussed above which pursue many different types of applications of PHAs, Tepha focuses exclusively on medical device applications.

- Tepha’s materials offer superior flexibility, elasticity, and biocompatibility.

- Tepha’s fiber-based products offer excellent tensile strength and strength retention.

- TephaFLEX®, a flexible and extensible polymer that is absorbable by the human body, is the first of the company’s PHA materials to be used in FDA-cleared medical devices. Products made by using TephaFLEX® include surgical suture, surgical mesh, surgical film, and a composite mesh. Devices that are currently in development could lead to more complex products, including devices for anterior cruciate ligament repair, intracardiac defect closure, and absorbable cardiovascular stents.

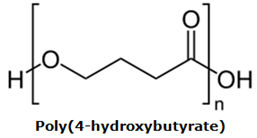

- TephaFLEX®differs from the PHAs produced by the five manufacturers discussed above in that, while their PHAs are based on poly(3-hydroxybutyrate) (P3HB) and copolymers of 3-hydroxybutyrate, TephaFLEX® is based on poly(4-hydroxybutyrate) (P4HB).

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

- Once implanted, P4HB will degrade in the body primarily by hydrolysis to produce 4HB. This monomer is a normal constituent of the mammalian body. It is found within a variety of tissues, including brain, heart, kidney, liver, lung, muscle and brown fat. The body metabolizes 4HB rapidly. Its half-life is approximately 27 minutes. To ensure the safety of P4HB, the biological effects of the polymer and devices made from it have been evaluated extensively both in vitro and in vivo.

- Tepha is also exploring opportunities to develop devices made from its elastomeric absorbable TephELAST®

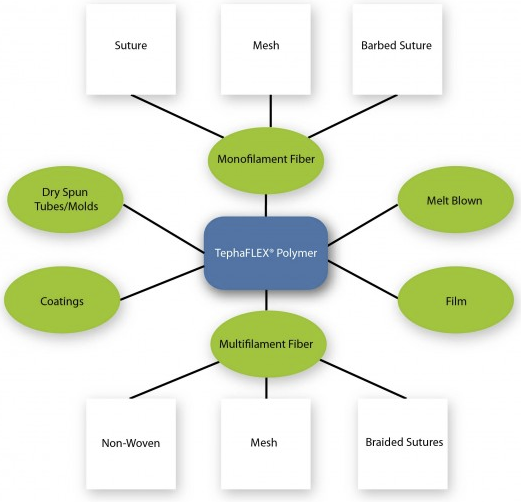

- TephaFLEX® and TephELAST® materials can be extruded, injection molded, solution cast, or made into microspheres as well as other forms. Some of the available manufacturing options and fabricated product forms for TephaFLEX® are shown below.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

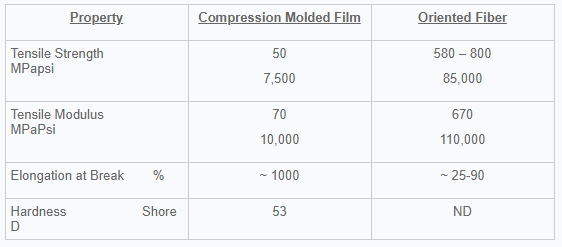

- The typical mechanical properties of TephaFLEX® are listed below.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()

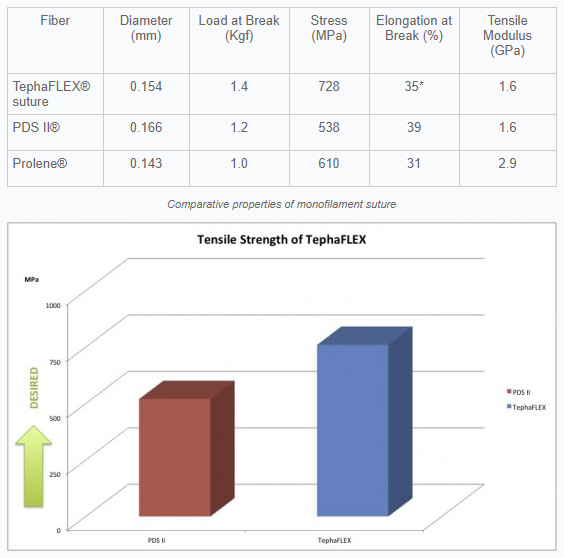

- The properties of monofilament suture produced from P4HB are shown in the table below. Comparative data for polypropylene and polydioxanone (PDO, the chemical name for PDS®) sutures are also shown. These data demonstrate the superior strength characteristics of the P4HB monofilament, with it being 35% stronger than polydioxanone and 19% stronger than polypropylene suture.

![Polyhydroxyalkanoates Completely Microbial Polyesters Polyhydroxyalkanoates Completely Microbial Polyesters]()